01 Aug Interview with the VirtFuse experiment

The KYKLOS4.0 Open Call #2 is funding seventeen experiments that are developing technological solutions of value for the manufacturing domain.

The project will be releasing a series of interviews over the course of the coming weeks with the objective of promoting the work being implemented in these experiments and allowing our readers to understand potential uptake of the solutions being developed by them.

This is the last of the seventeen interviews with the experiments funded under the open call. Today, we interview the VirtFuse experiment.

* * * * *

Explain your project in one sentence.

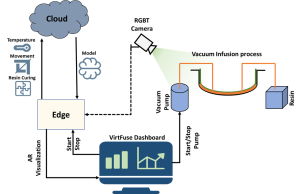

Edge-based digital twin model of vacuum infusion in next generation of manufacturing companies

How is KYKLOS4.0 project and the selected services (and components) bringing value to your project?

The KYKLOS 4.0 project is an innovative and comprehensive initiative that aims to speed up the way we design, develop, and manufacture complex products. By leveraging Industry 4.0 principles and advanced technologies, KYKLOS 4.0 provides a wide range of valuable services and components that significantly enhance our project’s overall efficiency, effectiveness, and competitiveness. The KYKLOS 4.0 project enables seamless integration of digitalisation and automation, which helps us streamline our manufacturing processes. Secondly, KYKLOS 4.0 promotes a collaborative approach by facilitating better communication and coordination among various stakeholders. Through the use of collaborative platforms, we can share ideas, resources, and expertise with more manufacturing companies leading to a more efficient development process and faster time-to-market. Moreover, the project supports a modular approach to product design, which allows us to create flexible and customisable products that can easily adapt to changing customer needs and market trends. This not only increases our competitiveness but also enables us to tap into new market segments, enhancing our business growth potential.

How is your solution contributing to circular manufacturing?

To make manufacturing processes more circular, companies should focus on the following strategies:

- Design for circularity: Prioritise modularity, repairability, and recyclability in product design to create sustainable products with extended lifespans and facilitate reuse.

- Optimise resource use: Implement strategies such as lean manufacturing and process optimisation to minimise waste and maximise resource utilisation.

- Collaborate with stakeholders: Foster collaboration with suppliers and partners to promote circular practices across the supply chain and drive collective improvement in resource efficiency.

- Embrace new business models: Explore alternative business models that promote circularity, such as product-as-a-service, remanufacturing, and sharing economy.

- Foster innovation: Invest in research and development to identify innovative solutions that promote circularity in manufacturing practices.

To support these strategies and accelerate the transition to circular manufacturing processes, companies can benefit from the KYKLOS 4.0 project. KYKLOS 4.0 offers a modular approach to product design, advanced data analytics, and collaborative platforms that enable companies to optimise resource use, improve collaboration with stakeholders, and foster innovation in circular practices. By harnessing the capabilities of KYKLOS 4.0, businesses can create long-term value for themselves, the environment, and society.

How will your solution be replicated and used in other manufacturing environments?

Conveniently, our VirtFuse solution can be customised and applied to other industrial machines which generate heat / movement patterns such as injection molding machines. Such equipment is frequently found in the food industry, automotive, medical & pharmaceutical, agricultural and electronics industries. Our use case with the industry partner in Europe will generate sufficient publicity for VirtFuse in general, and our solution in particular, to be widely accepted as a crucial need in manufacturing companies to reduce use of raw material and close the loop of circular manufacturing. Production optimisation as a service will be a paradigm in the future pioneered by on-the-edge AI solutions like VirtFuse. We can continuously evolve and improve VirtFuse by incorporating feedback from users, staying abreast of advancements in AI and manufacturing technologies, and adapting to emerging trends in circular manufacturing. This commitment to innovation and refinement will ensure that our solution remains at the forefront of sustainable manufacturing practices.

What advice would you give to companies wishing to make their manufacturing processes more circular?

To make manufacturing processes more circular, companies should focus on the following strategies:

- Design for circularity: Prioritise modularity, repairability, and recyclability in product design to create sustainable products with extended lifespans and facilitate reuse.

- Optimise resource use: Implement strategies such as lean manufacturing and process optimisation to minimise waste and maximise resource utilisation.

- Collaborate with stakeholders: Foster collaboration with suppliers and partners to promote circular practices across the supply chain and drive collective improvement in resource efficiency.

- Embrace new business models: Explore alternative business models that promote circularity, such as product-as-a-service, remanufacturing, and sharing economy.

- Foster innovation: Invest in research and development to identify innovative solutions that promote circularity in manufacturing practices.

To support these strategies and accelerate the transition to circular manufacturing processes, companies can benefit from the KYKLOS 4.0 project. KYKLOS 4.0 offers a modular approach to product design, advanced data analytics, and collaborative platforms that enable companies to optimise resource use, improve collaboration with stakeholders, and foster innovation in circular practices. By harnessing the capabilities of KYKLOS 4.0, businesses can create long-term value for themselves, the environment, and society.

* * * * *

About the VirtFuse project

The VirtFuse project –Smart circular-compliant Vacuum infusion in Industry 4.0: Mixed cloud-edge digital twin model of vacuum infusion in next generation of manufacturing companies – is implemented by two partners: iThermAI B.V. (Belgium), Trygons SA (Greece)

Summary: The main objective of the project is to create a mixed cloud-edge digital twin model of vacuum infusion in next generation of #manufacturing companies developing an AR dashboard to visualize the multidimensional data of the process to the responsible operator in real-time to allow monitoring the spread, curing level, as well as possible defects.