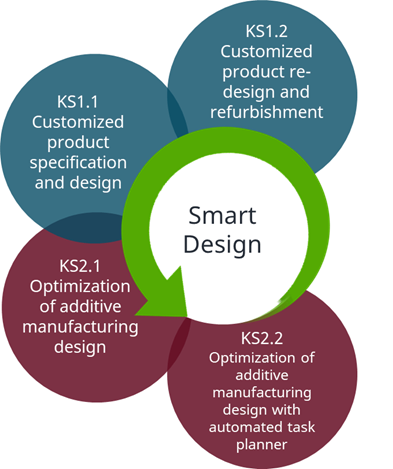

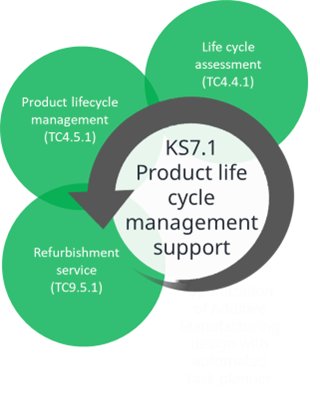

KYKLOS 4.0 technology involves a set of intelligent tools for real-time analytics, prediction, and recommendation systems, integrated into the KYKLOS 4.0 services. KYKLOS 4.0 Circular Manufacturing Framework consists of 15 Services (KS1.1-6.2 + KS7.1) which are grouped in 6 main Exploitation Packages (EPs) and 2 main categories (namely “Smart Design” and “Production Optimization”). KS7.1 titled “Product Lifecycle Management Support” covers both categories enabling data management, carbon footprint/environmental impact monitoring, and certification. Below you can find more information about KYKLOS 4.0 Services

Services

EP1 Personalized product design and refurbishment (including KS1.1 and KS1.2) | Toggle to view

The Services support both the customer and the product designer. First, by helping the customer to provide the specific requirements of an individual fully customized product. Second, the product designer can convert the requirements defined by the customer into individualized product specifications and complete a customer-oriented design for additive manufacturing product. In this way, the design process runs efficiently and smoothly, which represents savings in time and cost.

EP2 Additive manufacturing design and automation (including KS2.1 and KS2.2) | Toggle to view

The Services support the product designer on the decision-making about the additive manufacturing design of a specific product in terms of best materials selection, best specification sizes and orientation or simulation of the final product. As a result, the manufacturing process is improved by accelerating and enhancing the quality of the design process and consequently, the KYKLOS 4.0 Services provide enhanced operational effectiveness in terms of cost and time.

EP3 Predictive maintenance planning and scheduling (including KS3.1 and KS3.2) | Toggle to view

The Services support the maintenance team (i.e., maintenance manager, maintenance supervisor, maintenance engineer, maintenance operator) which is responsible for the equipment of the production line. The KYKLOS 4.0 Services guide the maintenance team on the optimal management of the maintenance tasks, resources, and materials. The Services include AI techniques for advanced data analytics to provide predictions concerning maintenance operations.

EP4 AR-based predictive maintenance operations (including KS4.1, KS4.2, KS4.3, and KS4.4) | Toggle to view

The Services support the maintenance team (i.e., maintenance manager, maintenance supervisor, maintenance engineer, maintenance operator) which is responsible for the equipment of the production line. The KYKLOS 4.0 Services guide the maintenance team on the optimal management of the maintenance tasks, resources, and materials. The Services include AI and AR techniques to provide predictions and guidance concerning maintenance operations.

EP5 AR-based toolkit for production (including KS5.1 and KS5.2) | Toggle to view

The Services support the manufacturing operator during the production phase, including preparation of the production, the production phase itself, post-production, and assembly. KYKLOS 4.0 Services offer innovative technologies such as AR and AI techniques for improving the guidance and support of the process to the operators.

EP6 Life cycle assessment of circular products (including KS6.1 and KS6.2) | Toggle to view

The services support the production manager or plant manager by monitoring in real-time the production as well as by providing simulation of the process in case some of the inputs change. KYKLOS 4.0 Services also provide a decision support system based on the indicators calculated during the production phase to enhance both the production and the circular indicators. Also, the Services enable the orchestration of multiple components involved into the manufacturing process of a product line so all of them are synchronized and efficiently managed.

KS7.1 “Product Lifecycle Management Support” covers the whole value chain of production by providing product life cycle data management, carbon footprint & Life Cycle Assessment (LCA) monitoring ( circularity and sustainability related KPIs monitoring), and refurbishment & certification support (performing a trustworthy tracking of the different parts of the final product in order to ensure that all parts comply with the user requirements).